Products

- Gate Valves

- Globe Valves

- Check Valves

- Double Block & Bleed Valves

- Ball Valves

- Butterfly Valves

- Pneumatic Actuators

- Actuators Hydraulic

- Gas Over Oil Actuators

- Electro Hydraulic Actuators

- Self Contained Actuators

- Control Accessories

- Butt Weld End Fittings

- Forged Flanges

- High Pressure/ High Temperature Services

- HIPPS Application

- Deep Water Subsea

- Nuclear & Aerospace Industry

VALVES

ACTUATORS AND CONTROLS

PIPE FITTINGS

ENGINEERED PRODUCTS

Gate Valves for Process & Pipelines

| Manufacturing design | As per API 602, ASME B16.34, API 6D | Size | 1/4" - 56" |

| Pressure Rating | #150 to #4500 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Type | Bolted bonnet, Welded bonnet, Pressure seal bonnet |

| End connection | Flanged, Screwed, Socket weld, Buttweld |

| Testing | As per API 598 |

Gate Valves for cryogenic applications

| Manufacturing design | As per BS 5352, BS 6364 | Size | 1/4" - 4" |

| Pressure Rating | #150 to #1500 |

| Material | SS 304, SS 304L, SS 316, SS 316L |

| Type | Extended bonnet bolted type, Extended bonnet welded type for cryogenic application |

| End connection | Flanged, Socket weld, Buttweld |

| Testing | As per BS 5352, BS 6364 |

API 6A Gate Valves

| Manufacturing design | As per API 6A | Size | 1-13/16” to 9” |

| Pressure Rating | 2000, 3000, 5000, 10000 and 15000 psi | Product specification level | PSL 1, PSL 2 and PSL 3 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Type | Bolted bonnet, Extended bonnet for cryogenic application |

| End connection | Flanged ends according to API 6A RF/ RTJ 6B/ 6BX type |

| Testing | As per API 6A |

Globe Valves for Process Industry

| Manufacturing design | As per BS 5352, ASME B16.34, BS 1873 | Size | 1/4" - 36" |

| Pressure Rating | #150 to #4500 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Type | Bolted bonnet, Welded bonnet, Pressure seal bonnet, "Y" Type |

| End connection | Flanged, Screwed, Socket weld, Buttweld |

| Testing | As per API 598 |

Globe Valves for cryogenic applications

| Manufacturing design | As per BS 5352, BS 6364 | Size | 1/4" - 4" |

| Pressure Rating | #150 to #1500 |

| Material | SS 304, SS 304L, SS 316, SS 316L |

| Type | Extended bonnet bolted type, Extended bonnet welded type for cryogenic application |

| End connection | Flanged, Socket weld, Buttweld |

| Testing | As per BS 5352, BS 6364 |

Check Valves

| Manufacturing design | As per BS 5352, ASME B16.34, BS 5352, BS 6364, BS 1868,API 594 | Size | 1/4" - 36" |

| Pressure Rating | #150 to #4500 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Type | Bolted cover (also suitable for cryogenic application), Welded cover, "Y" type |

| End connection | Flanged, Screwed, Socket weld, Buttweld |

| Testing | As per API 598, BS 6364 |

Non Slam Check Valves

| Manufacturing design | As per API 6D, API 594, ASME B16.34 | Size | 1/4" - 24" |

| Pressure Rating | #150 to #2500 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Type | Basic check valve, Vaccum breaker check valve, Restrictor check valve |

| End connection | Flanged, Wafer, Buttweld |

| Testing | As per API 598, MSS SP-61 |

API 6A Check Valves

| Manufacturing design | As per API 6A | Size | 1-13/16” to 9” |

| Pressure Rating | 2000, 3000, 5000, 10000 and 15000 psi | Product specification level | PSL 1, PSL 2 and PSL 3 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Type | Bolted cover |

| End connection | Flanged ends according to API 6A RF/ RTJ 6B/ 6BX type |

| Testing | As per API 6A/ ISO 15761 |

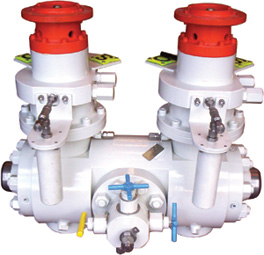

Double Block And Bleed Valves

| Manufacturing design | As per ASME VII, ASME B16.34 | Size | 1/2" to 24" |

| Pressure Rating | #150 to #2500 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Seats | Soft or metal seated |

| End connection | Flanged |

| Testing | As per API 598, API 6D, ISO 15848 |

Side Entry Ball Valves

| Manufacturing design | As per API 6D, EN ISO 17292, ASME B16.34 | Size | 1/2" - 56" |

| Pressure Rating | #150 to #2500 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Seats | Soft seated & Metal seated |

| Type | Trunnion Mounted, Side Entry, Bolted, Fully Welded |

| End connection | Flanged, RTJ, Buttweld |

| Testing | As per API 598, API 6D |

Top Entry Ball Valves

| Manufacturing design | As per API 6D, EN ISO 17292, ASME B16.34 | Size | 1/2" - 56" |

| Pressure Rating | #150 to #2500 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Seats | Soft seated & Metal seated |

| Type | Trunnion Mounted, Top Entry, Bolted, Fully Welded |

| End connection | Flanged, RTJ, Buttweld |

| Testing | As per API 598, API 6D |

API 6A Ball Valves

| Manufacturing design | As per API 6A |

| Size | 2” to 24” |

| Pressure Rating | 2000, 3000, 5000, 10000 and 15000 psi |

| Product specification level | PSL 1, PSL 2 and PSL 3 | Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Type | Bolted body connection |

| End connection | Flanged ends according to API 6A RF/ RTJ 6B/ 6BX type |

| Testing | As per API 6A |

Cryogenic Ball Valves

| Manufacturing design | As per API 6D, API 608, BS 6364, ASME B16.34 | Size | 1/2" - 42" |

| Pressure Rating | #150 to #2500 |

| Material | SS 304, SS 304L, SS 316, SS 316L |

| Seats | Soft seated & Metal seated |

| Type | Trunnion Mounted, Top Entry, Bolted |

| End connection | Flanged, Buttweld |

| Testing | As per API 598, API 6D |

Butterfly Valves for Process Industry

| Manufacturing design | As per API 609, ISO 5752, ASME B16.34 | Size | 3" - 120" |

| Pressure Rating | #150 to #2500 |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Type | Side Entry, Torque seated Triple Eccentric design |

| End connection | Flanged, Lugged, RTJ, Buttweld |

| Testing | As per API 598, API 6D |

Butterfly Valves for cryogenic applications

| Manufacturing design | As per API 609, ISO 5752, ASME B16.34 | Size | 3" - 120" |

| Pressure Rating | #150 to #2500 |

| Material | SS 304, SS 304L, SS 316, SS 316L |

| Type | Side Top Entry, Extended stem, Torque seated Triple Eccentric design |

| End connection | Flanged, Lugged, RTJ, Buttweld |

| Testing | As per API 598, API 6D |

Pneumatic Actuators

| Product Range | Material Range | Valve Application | Quarter turn (Rotary) and Linear |

| Function type | Spring return, Double acting |

| Torque/ thrust Range | Quarter turn: up to 1,000,000 Nm for single acting up to 2,000,000 Nm for Double acting Linear: up to 400,000 N for single acting up to 3,000,000 N for Double acting |

| Ambient temperature Range | 1) Standard operating temperature range -30°C / +100°C 2) Special low temperature application up to -60°C 3) Special high temperature application up to +200°C |

| Pressure range | Supply pressure up to 12 bar design |

| SIL Suitability | SIL-3 |

| MOC | Carbon steel and Stainless steel |

| Certifications | PED, CE, ATEX, EAC, GOST, IEC, INMETRO |

Hydraulic Actuators

| Product Range | Material Range |

| Valve Application | Quarter turn (Rotary) and Linear |

| Function type | Spring return, Double acting |

| Torque/ thrust Range | Quarter turn: up to 1,000,000 Nm for single acting up to 2,000,000 Nm for Double acting Linear: up to 400,000 N for single acting up to 10,000,000 N for Double acting |

| Ambient temperature Range | 1) Standard operating temperature range -30°C / +100°C 2) Special low temperature application up to -60°C 3)Special high temperature application up to +200°C |

| Pressure range | Supply pressure up to 400 bar design |

| SIL Suitability | SIL-3 |

| MOC | Carbon steel and Stainless steel |

| Optional | Accumulator, Fire proofing, NAS 6 cleaning |

Direct Gas and Gas Over Oil Actuators

| Valve Application | Quarter turn (Rotary) and Linear | Function type | Spring return, Double acting |

| Torque/ thrust Range | Quarter turn: up to 1,000,000 Nm for single acting up to 2,000,000 Nm for Double acting Linear: up to 400,000 N for single acting up to 10,000,000 N for Double acting |

| Ambient temperature Range | 1) Standard operating temperature range -30°C / +100°C 2) Special low temperature application up to -60°C 3)Special high temperature application up to +200°C |

| Pressure range | Supply pressure up to 1440 psi design (all types of gas composition including Sour and wet gas) |

| SIL Suitability | SIL-3 |

| MOC | Carbon steel and Stainless steel |

| Optional | Emergency Back up tank, Mechanical interlocking system, Insulated control station. |

Electro Hydraulic Actuators

| Valve Application | Quarter turn (Rotary) and Linear | Function type | Spring return, Double acting |

| Torque/ thrust Range | Quarter turn: up to 1,000,000 Nm for single acting up to 2,000,000 Nm for Double acting Linear: up to 400,000 N for single acting up to 10,000,000 N for Double acting |

| Ambient temperature Range | 1) Standard operating temperature range -30°C / +100°C 2) Special low temperature application up to -60°C 3)Special high temperature application up to +200°C |

| Supply | Supply 400 VAC/ 3 Phase, 50 Hz (Optional Voltages on request) Hydraulic fluid supply: up to 350bar design |

| Standard Functionalities | ESD (Emergency Shut down), Remote and Local PST (Partial stroke test) Pressure alarm Voltage Alarm Oil level protection Position and Pressure transmitter |

| SIL Suitability | SIL-3 |

| MOC | Carbon steel and Stainless steel |

| Optional | Emergency Back up tank, Mechanical interlocking system, Insulated control station. Service: On/off, modulating service and Ultra-fast closing (<200ms) |

Self Contained Actuators

| Valve Application | Quarter turn (Rotary) and Linear | Function type | Spring return |

| Torque/ thrust Range | Quarter turn: up to 1,000,000 Nm for single acting Linear: up to 400,000 N for single acting |

| Ambient temperature Range | 1) Standard operating temperature range -30°C / +100°C 2) Special low temperature application up to -60°C |

| Supply | Hydraulic supply up to 350bar design |

| Standard Functionalities | Zero emission solution Modular Manifold design Fail safe design Closed loop arrangement Adaptable with telemetry systems, SCADA or other remote-control signals. |

| SIL Suitability | SIL-3 |

| MOC | Carbon steel and Stainless steel |

| Optional | NACE compliance, Line break detection, Emergency Backup tank, Mechanical interlocking system, Insulated control station. Service: On/off, modulating service and Ultra-fast closing (<200ms) |

Controls & Accessories

| Fire proofing (as per UL 1709) |

| Options: Rigid Stainless-steel panel, Flexible Blanket type, Resin based Intumescent compound. |

| Remote indicators |

| Quick Exhaust valve |

| Damper (Aluminum alloy or 316SS) |

| Mechanical partial stroke device |

Butt Weld End Fittings

| Product Range | Material Range | Pipes | Carbon and Alloy steel for elevated temperature |

| Lateral Tees | High test steel for Pipeline and Offshore |

| Heavy Special Forgingsl | Carbon and Alloy steel for low temperature service |

| Manifold | Stainless steel |

| Y Pieces | Ferritic/Austenitic stainless Steel |

| Sphere Tees | Nickel and Nickel Alloys |

| Pigging Tees | Special alloys on request |

| Reducers | |

| Elbows (LR/ SR) | |

| Hemispeherical Heads | |

| Special Products |

Forged Steel Flanges

| Product Range | Material Range | Manufacturing design | ANSI B 16.5 |

| Other Design Standards | ASME B16.47 - BS 3293 – AWWA – UNI EN – API - ISO |

| Size | 1/2" - 36" |

| Pressure Rating | #150 to #2500 |

| Materials | FeCarbon steel, Stainless Steel, Duplex and Super Duplex stainless steel,Nickel, Cupro Nickel, and special alloy steels |

| Types | Welding Neck, Slip on, Blind, Screwed, Socket Weld, Lap joint, Reducing, Orifice Flanges, Long welding Neck |

| Certifications | ISO-9001, PED, AD 2000, Lloyd-s, API, Norsok |

High Pressure/ High Temperature Services

| Pressure Rating | To 15,000 psi |

| Bore Sizes | 2" to 24" |

| Material | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Actuation | Hydraulic, Electric, Manual, Lever and ROV |

| Standards | API 6A, API 6D, API 6AV1, ISO 10423, ISO 13628 |

HIPPS Application

| Pressure Rating | To 20,000 psi |

| Temperatures | -46 Deg C to +190 Deg C |

| Bore Sizes | 1" to 24" |

| Material Options | Carbon Steel, Alloy Steels and CRA |

| Configurations | Top or Side Entry, Full or Reduced bore, Flanged, Buttweld, Compact Flange, or other proprietary connections |

| Applications | Surface & Subsea |

| Actuation | Hydraulic (Double and Spring Return) |

| Standards | API 6A, API 6D, API 6DSS, API 17D, API 6AV1, API 170, ISO 10427, ISO 14313, IEC 61508/ IEC 61511 |

Through Conduit Gate Valves

| Pressure Rating | API 2,000 to 20,000 psi |

| Temperatures | -100 Deg C to +190 Deg C |

| Water Depths | To 3000m | Bore Sizes | 2" to 42" |

| Material Options | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Configurations | Full or Reduced bore, Flanged, Buttweld, Compact Flange, or other proprietary connections |

| Applications | Surface & Subsea, Abrasive flow, Process Isolation, High Integrity Pipeline Protection Systems, Emergency Shutdown, Hot tapping, Pig Launcher/ Receiver, High temperature, High pressure, |

| Actuation | Hydraulic, Electric, Manual, Lever and ROV |

| Standards | API 6A, API 6D, API 6DSS, API 17D, API 6AV1, ISO 10423, ISO 13628, ISO 14313, ISO 14723 |

Subsea Ball Valves

| Pressure Rating | API 2,000 to 20,000 psi |

| Temperatures | -100 Deg C to +190 Deg C |

| Water Depths | To 3000m | Bore Sizes | 2" to 42" |

| Material Options | Carbon steel, Stainless Steel, Duplex and Super Duplex stainless steel, Titanium, Monel, Inconel and special alloy steels |

| Configurations | Top or Side Entry, Partially or fully clad, Full or Reduced bore, Floating or Trunnion Mounted, Flanged, Buttweld, Compact Flange, or other proprietary connections |

| Applications | Surface & Subsea, Abrasive flow, Process Isolation, Hot tapping, Pig Launcher/ Receiver, High temperature, High pressure, |

| Actuation | Hydraulic, Electric, Manual, Lever and ROV |

| Standards | API 6A, API 6D, API 6DSS, API 17D, API 6AV1, ISO 10423, ISO 13628, ISO 14313, ISO 14723 |

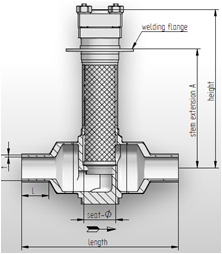

Cryo - Filter

| Service Fluid | N2, O2, Ar, H2, He, NG* |

| Operating Fluid Temperature | -190 deg C to +50 deg C |

| Body sealing | Metal seal ring | Bore Sizes | 10 mm to 100 mm |

| Pressure Rating | upto 40 bar |

| Material | Stainless Steel |

| Welding flange | according to specification for vacuum insulated tubes |

| Material certificates | DIN EN 10204/3.1 AD2000-A4 |

* Further sizes and pressure ranges on request

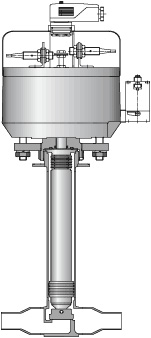

Globe Valve with Magnetic Actuator

| Service Fluid | N2, O2, Ar, H2, He, N2O, CO2, NG* |

| Operating Fluid Temperature | -30 deg C to +50 deg C |

| Seat sealing | Metal/ PCTFE, Metal/ PTFE, Metal/ Metal | Bore Sizes | 10 mm to 50 mm |

| Pressure Rating | upto 10 bar |

| Material | Stainless Steel |

| Installation | In close rooms |

| Material certificates | DIN EN 10204/3.1 AD2000-A4 |

* Further sizes and pressure ranges on request

Springless Cryogenic Non-Return Valve

| Service Fluid | N2, O2, Ar, H2, He, N2O, CO2, NG* |

| Operating Fluid Temperature | -196 deg C to +50 deg C |

| Seat sealing | Metal/ Soft seal | Bore Sizes | 10 mm to 40 mm |

| Pressure Rating | upto 40 bar |

| Material | Stainless Steel |

| Minimum opening pressure | < 0.03 bar |

| Material certificates | DIN EN 10204/3.1 AD2000-A4 |

* Further sizes and pressure ranges on request

Cryogenic Globe Valve with Stainless Steel Bellow

| Service Fluid | N2, O2, Ar, H2, He, N2O, CO2, NG* |

| Operating Fluid Temperature | -196 deg C to +50 deg C |

| Seat sealing | Metal/ PCTFE, Metal/ PTFE, Metal/ Metal | Bore Sizes | 8 mm to 100 mm |

| Pressure Rating | upto 25 bar |

| Material | Stainless Steel |

| Welding flange | according to specification for vacuum insulated tubes |

| Material certificates | DIN EN 10204/3.1 AD2000-A4 |

* Further sizes and pressure ranges on request

Pressure Relief Valve

| Service Fluid | N2, O2, Ar, H2, He, Vacuum etc |

| Operating Fluid Temperature | 20 deg C |

| Seat sealing | Soft seal (PCTFE/ Viton) | Bore Sizes | 10 mm to 50 mm |

| Response Pressure | 100 - 1000 mbar |

| Material | Aluminium or Stainless Steel |

| Leakage Rate | to atmosphere 0.001 mbar l/s |

| Material certificates | DIN EN 10204/3.1 AD2000-A4 |

* Further sizes and pressure ranges on request